Wind Turbine Gearbox Inspections - Windnostics Limited

Wind Turbine Gearbox Inspections

Contact Windnostics on TEL: 01352 710600 or email: enquiries@windnostics.com to arrange your end of warranty wind turbine gearbox inspections, borescope / endoscope remote visual inspection, pre-site hand over commissioning and root cause investigation of wind turbine gearbox or generator noise, vibration and CMS alarms.

With a background of over 30 years in non-destructive testing, machine diagnostics and condition monitoring, Windnostics technicians can easily determine the source and severity of your wind turbine noise, vibration and investigate CMS alarms as well as other underlying issues affecting your asset.

We provide a 24 hour emergency call-out service and fast turnaround of analysis and reporting, typically within 24 hours of completing the site survey.

We are members of the British Institute of Non Destructive Testing (BINDT), United Kingdom Thermography Authority (UKTA), Renewable UK and SafeContractor, with clients such as EDF EN Services UK Limited, Ecogen and Peel Energy to name just a few.

Prevention Is Better Than Cure

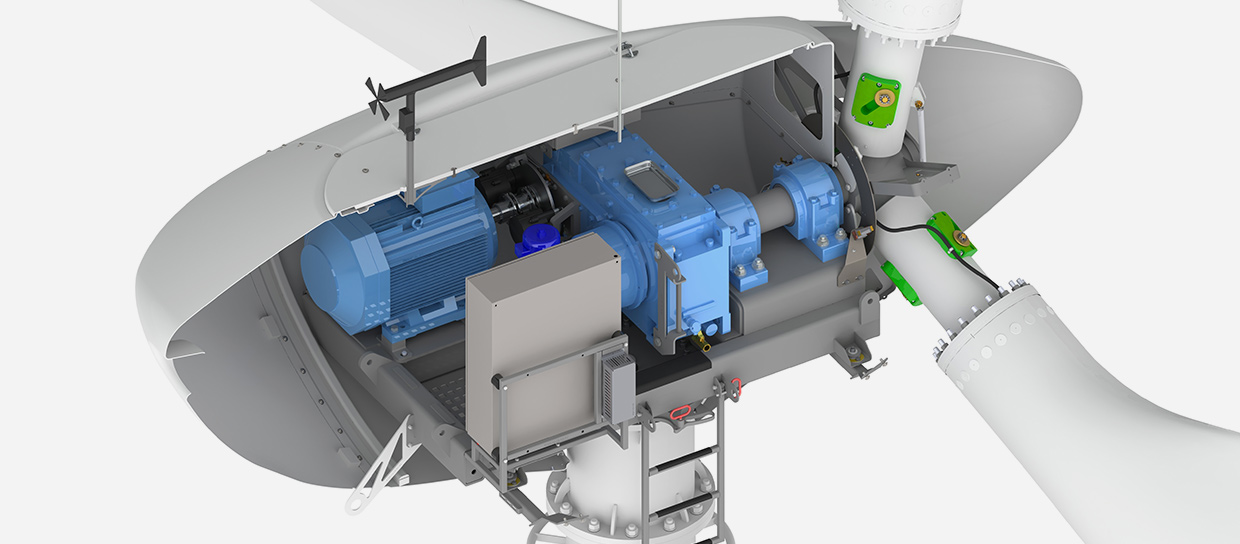

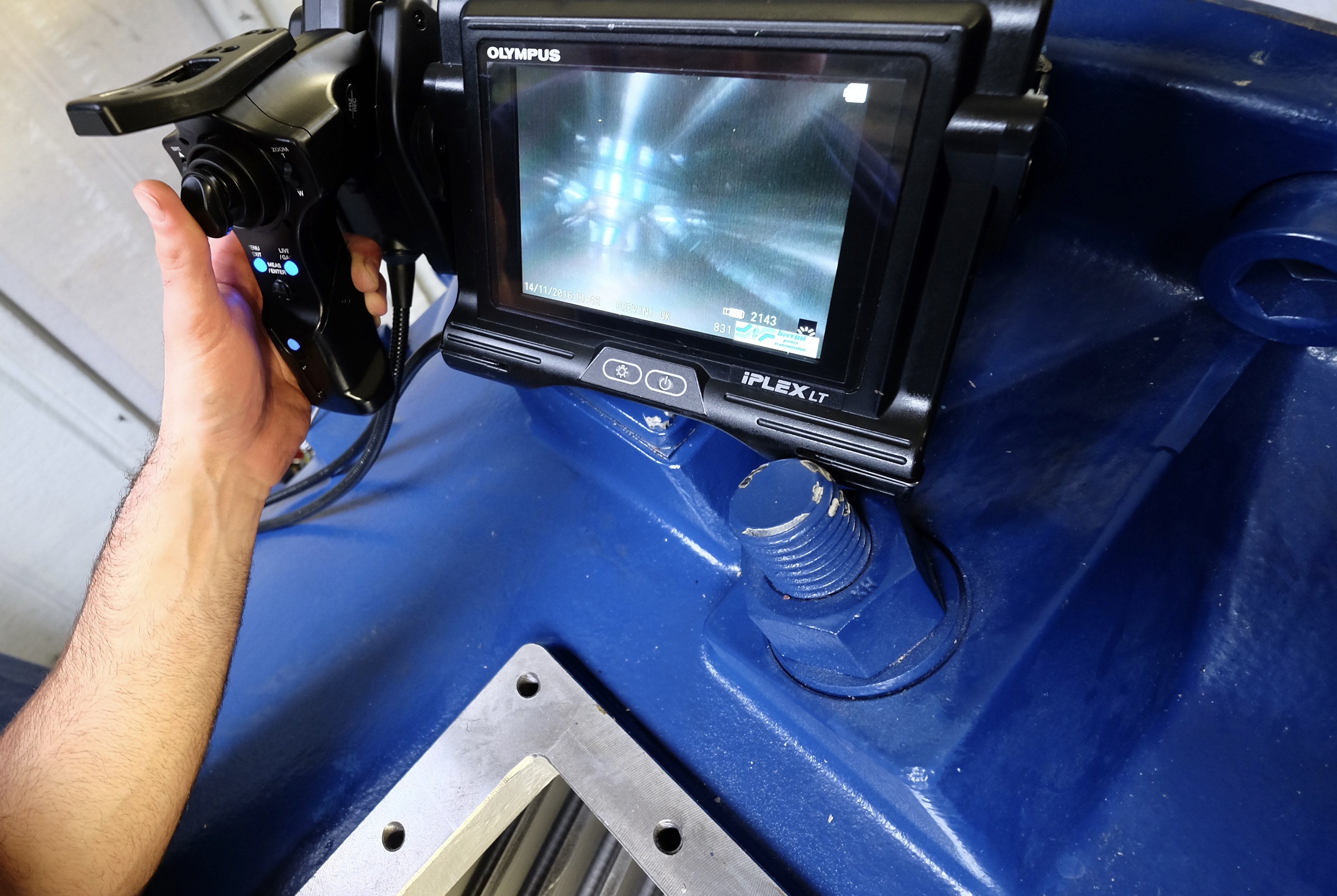

Using an industrial grade high resolution endoscope (also referred to as a borescope) to determine varying degrees of gearbox internal component wear and damage

Multi-channel FFT (fast Fourier transform) spectral and real-time recorded analysis to determine operational condition and highlight underlying mechanical issues affecting the gearbox and the entire drivetrain including the generator and main rotor shaft bearings

Using a professional hand-held sound level meter with onboard FFT (fast Fourier transform) capability, we can determine mechanical anomalies at defined frequencies at the base of the wind turbine, giving a useful 'heads up' assessment before carrying out any further NDT inspections

To determine particle and component wear, water/acid content and ISO cleanliness in the gearbox

Predict, Plan and Prevent

Independent commissioning and conformance testing prior to warranty expiration and site hand over highlights any defects prior to the end of warranty term, thereby saving additional expenditure and offsetting all rectification costs to the Original Equipment Manufacturer.

By implementing our services, we can assist wind farm owners and operators to plan, schedule and coordinate maintenance with minimum downtime with a clear and focused approach on optimising uptime of wind turbine power generation.

As we are completely independent and not affiliated to any particular gearbox, bearing or wind turbine manufacturer and completely impartial, we are in a unique and advantageous position to provide completely unbiased and accurate information with our inspections, with an emphasis on identifying the source of the problem and providing a practical, economically viable resolution.

By regularly collecting and analysing data from each wind turbine, Windnostics technicians can detect issues at an early stage in order to manage and minimise the risks of failure and cost per repair by providing a practical set of solutions and outline a cohesive maintenance strategy to prevent reoccurrence.

If you require any further information or would like to discuss how we could offer assistance to your organisation, please do not hesitate to contact us on TEL: 01352 710600 or email: enquiries@windnostics.com.